Design & Engineering

In todays digitised manufacturing environments, integrating tools, stations and machines that fully support automation and data exchange is crucial. Knowledge of software, standards, security and business processes combined with almost 4 decades of experience in mechanical design and electric engineering of connectivity solutions, will make us perfectly fit into your future.

Our 4.0 full life-cycle approach

Our goal is to be your connectivity technology partner, to be at your side from the moment the first idea comes to live. We want to guide and help you during each phase in the commercial live of a tool or machine. Both standard solutions and custom developments are backed by the Föhrenbach 4.0 full life-cycle approach. Thanks to our platform based solutions, we are able to adapt your machine to fit your future requirements.

1.0 Feasibility Study

Designing and building complex tools and machines should not be a journey into the unknown. Our engineers will study all aspects upfront to guarantee success. Often, customers already involve us in the prototyping of a new connector.

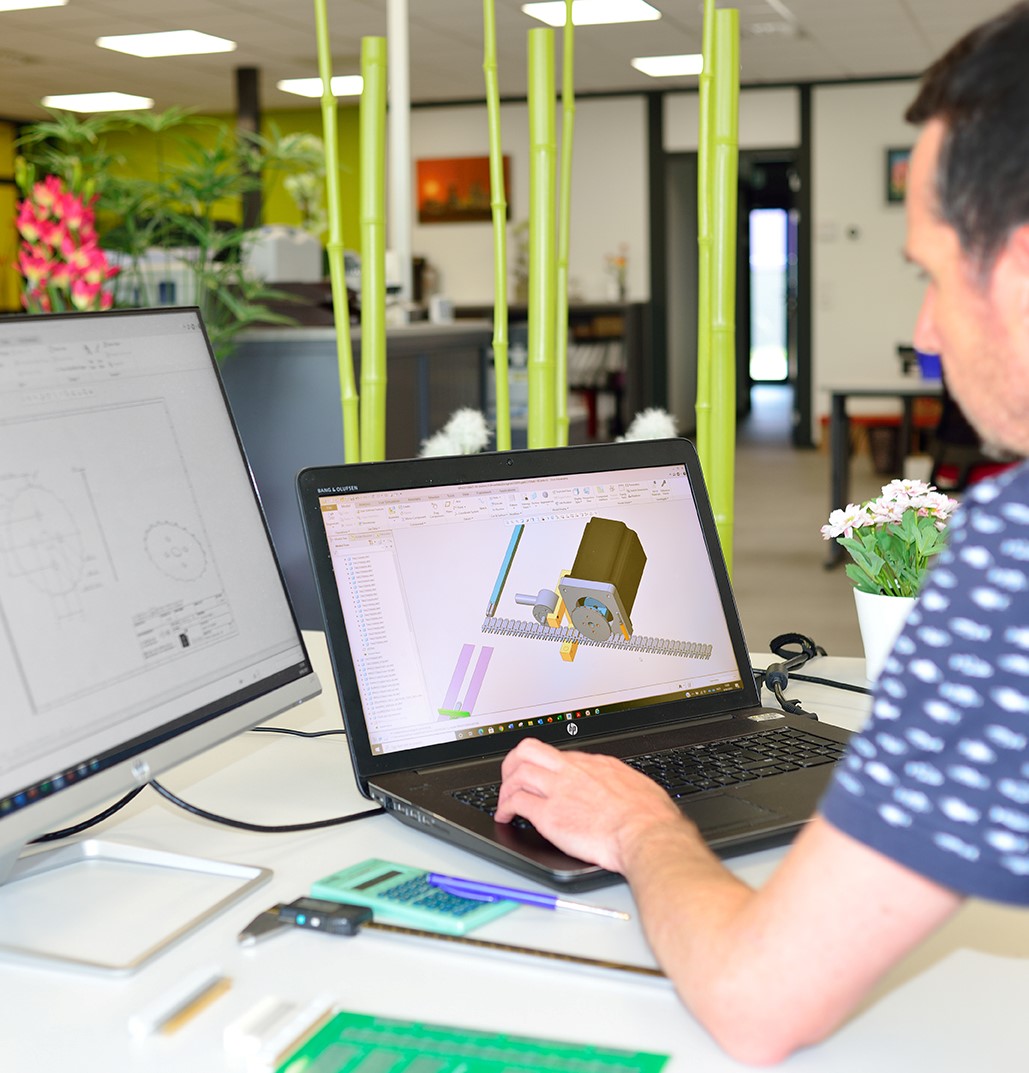

2.0 Design

Using the latest techniques and software applications, our team of specialists designs innovative connector assembly and fitting tools. Extensive process simulations are done to create the perfect machine for your application.

3.0 Production & Testing

Build to plan, outperforming expectations, that is what we promise you. We closely monitor each step in the production and assembly process of our stations and machines. We are committed to serve the industry with Tier 1 products. Our personal involvement in the fabrication, testing and quality checks is but one example of how we achieve this.

4.0 Installation, After-sales Service & Support

We commit ourselves to outstanding after-sales service and support for the Föhrenbach Application Tools you use. Custom machines, build on the exclusive Föhrenbach standard platforms can easily be adapted if your needs change. A Föhrenbach solution is a future proof investment.

Our 4-ever customizable Concept

It doesn’t matter if you chose for a standard Föhrenbach Application Tooling machine or for a custom designed solution. We understand that your constant innovations lead to new requirements. Over the years we have become strong at adapting existing installations to fit the new dimensions of the products you use and to expand their features with additional QC tools and software, to fully answer your and your customers current needs. Our unique Föhrenbach platform based approach is your guarantee for a flexible and future proof solution.

Our 4 Design Differentiators

Designing a high-performing machine or tool requires in depth knowledge of mechanics, software and safety concepts. At Föhrenbach Application Tooling, we are able to stand-out from the competition thanks to 4 key design differentiators. We master mechanics, we excel at electrics, we really know robotics and we stand for safety.

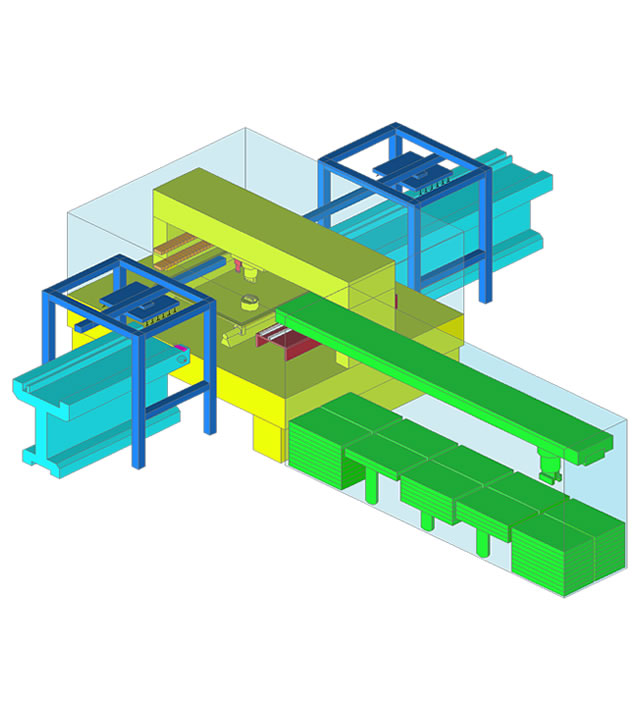

1. Mechanical Design

Our strength is understanding the forces at play in complex machinery. By making meticulous power calculations and by building virtual machine models, we simulate a real life production environment to create an unrivalled mechanical solution.

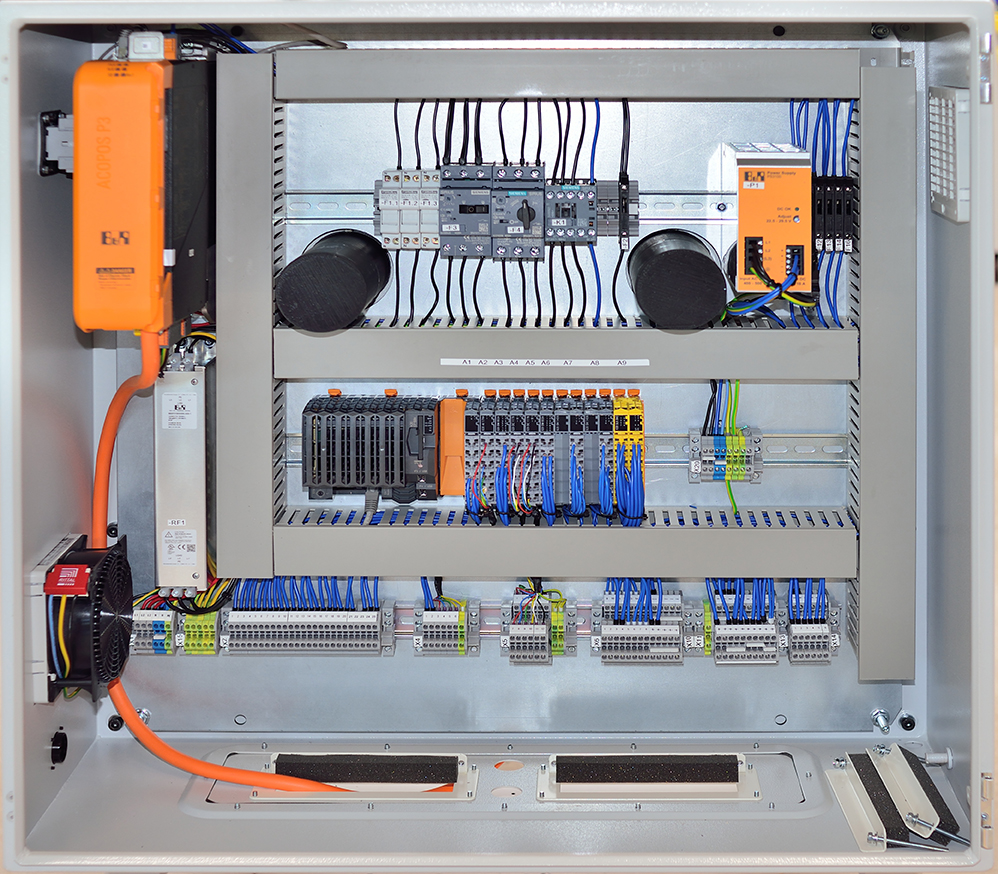

2. Electric Design

The underlying electric architecture of a Föhrenbach Application Tooling station or machine is designed to guarantee a balanced and reliable power distribution throughout a full production cycle. By using certified components and proven concepts, electrical failure is well below the industry average.

3. Robotics Design

Robotics can greatly contribute to a flexible automation of a connector application station or machine. Our engineers succeed in a perfect translation of computer generated instructions and commands into precision mechanical movements. Our robotics designs are a seamless extension of the software that brings your machine to live.

4. Safety Design

We think that people are a company's most valuable asset. Operational risk assessment is an integral part of our design process. We pro-actively monitor Health & Safety regulations to make our concepts compliant with the latest standards. The resulting ergonomic design of our tools guarantees that risks of personal injury are reduced to an absolute minimum.

Our Industry 4.0 Objective

Föhrenbach Application Tooling wants to play a key role in the transformation and automation of your manufacturing processes. We follow the FMEA methodology (Failure Mode and Effects Analysis) to detect and proactively cope with possible issues already early in the design phase of our machines. Thanks to this, we avoid costly and complex adaptions later on in the development and deployment phase of a project. For further reliability monitoring and validation, we use technologies like intelligent cameras & 3D laser scanners. HMI software, supporting for example the industry standard OPC UA protocol, will give your operators and engineers the right tools and controls to operate and maintain a Föhrenbach solution via an intuitive UI. In short, we can design and build connector assembly and application machines that support your digital transformation and that will help you build your Industry 4.0 Smart Factory.

Föhrenbach Application Tooling N.V.

Your Trusted Link To Interconnection Solutions.

If you have questions about our products, pricing, security, implementation or anything else, please contact us today. We speak English, French, German and Dutch.

“Helping companies solve connectivity challenges since 1984.”