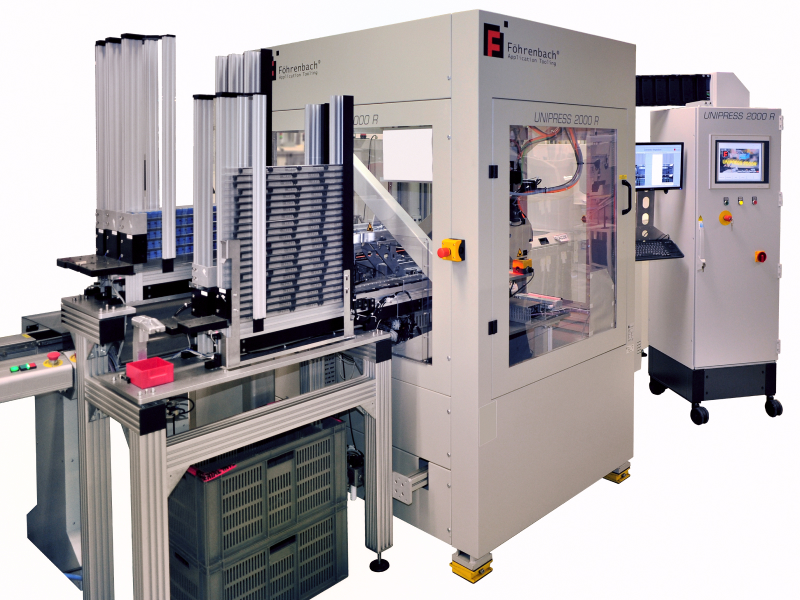

Unipress 2000 XL

| Contact type | All types of press-fit connectors |

|---|

Description

Full-automatic pick and place machine for inserting press-fit connectors in backplanes and daughterboards. The insertion spindel is driven by a electrical servo motor, which guarantees a very accurate position and can press up to 40 kN.

A force/distance control system controls the insertion cycle, checks for errors and guarantees the the connector is against the board after the insertion.

Way of working:

- The board can be loaded and unloaded manual or automatic with automatic board handlers.

- The connecters can be inserted manually (with tubes) or will be fed automatic with a component feeder (trays, tubes or bulk possible).

- The machine positions the board in XY direction automatically.

- Connectors are pick-up and insert full-automatic.

- Upper and anvils are changed automatic.

Features:

- The insertion force will be measured during the insertion operations and has to be between the adjusted minimum and maximum levels. If the insertion force is out of his range, the system gives a ‘Force Error’ and stops.

- Maximum board size: 950 x 635mm (37.4″ x 25″)

- Maximum connector length : 160mm (6,3″)

- The machine contains a ‘Board Error Correction’ system in order to cope with eventual positional tolerances of backpanels. A correction is made within 0,6 sec.

- It is possible to rotate the connector in steps of 15º. Rotation angle is written in the pattern program.

- The automatic insertion and anvil tool exchanging system can accept up to 20 different insertion blades.

A graphical editor allowing a flexible updating of the pattern programs is provided on the host PC. - Management information as board- and component counters and production timers are available at the host PC.

- UNIPRESS 2000 provides also a press only mode. As such, manually stuffed connectors can be pressed by means of the machine.

- The insertion speed depends on the type of the connector in process, and its position on the board. The average insertion speed is 15 connectors per minute.

Options:

- Anvils and insertion blades for several press-fit connectors. More info: Insert block and anvils.

- Bar code reader, for traceability.

- Automatic SMEMA compatible PCB conveyer.

- Automatic component feeder.

- Tube or stack feeders

- Bowl vibrators

Contact us if you can’t find a matching tool.

Get Price Info

Get Price Info (1)

Enter your email to receive a quote from one of our specialists.

"*" indicates required fields

Gerelateerde producten

Related products

-

HT115

The HT 115 is a polarizing tool for bergstick headers.

-

HM1 Male RA Repair Tool

Repair tool for Metral HM1 right angle male press-fit.

-

HM1 Female RA Repair Tool

Repair tool for Metral HM1 right angle female press-fit.

-

Unipress 1000 XXL

Automatic XY positioning of the pcb with connectors under the press axis.