Direct Attach

Föhrenbach Application Tooling supports the production of high speed cable assemblies, with an emphasis on the following connectors: SFP+, QSFP, InfiniBand, DensiShield, CXP, …

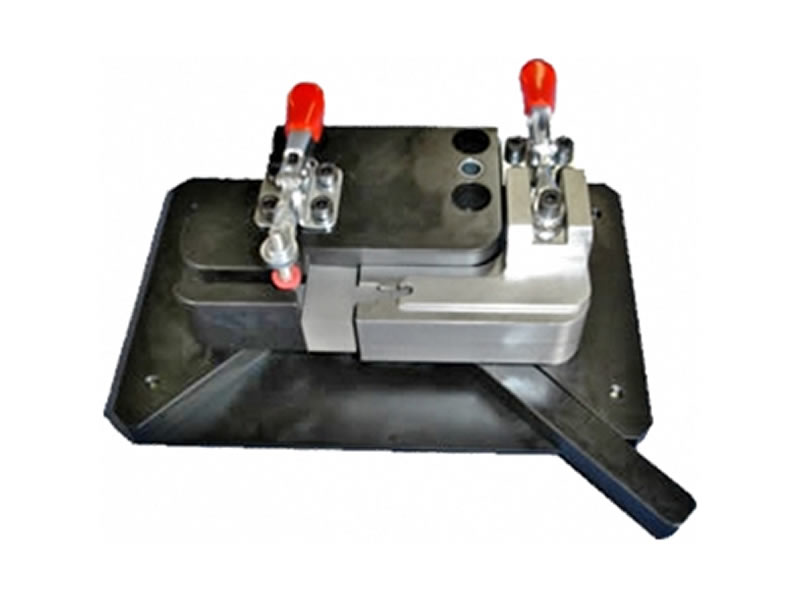

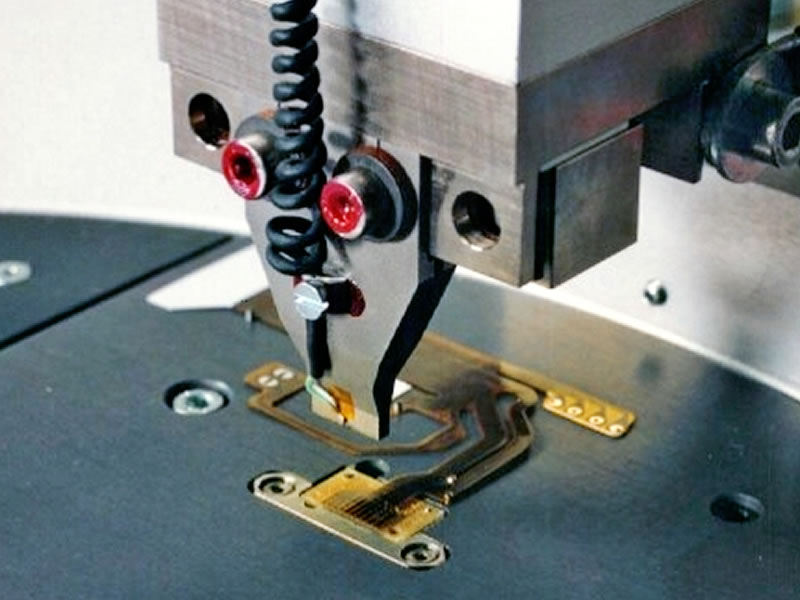

For the aforementioned connectors, the Twinax cable elements are soldered directly to the PCB in the connector. We support this process with systems ranging from simple jigs for hand soldering to automatic hot-bar soldering machines with integrated 2D and 3D camera control.

The production of high speed cable assemblies can be divided into cable prep, cable termination and post processing. At the customer’s request, we are also able to offer full support for the cable prep and post processing steps. In this, the following techniques are addressed: cutting the cables to length, printing on the cables, stripping the cables, coiling, high pressure over-moulding of strain reliefs, gluing (UV curing), low pressure over-moulding of the soldered PCB, continuity and high voltage electrical testing, cover closing, …

Cover closing is not only used with direct attach connectors. Depending on the type of connector, we make tools for riveting or hot or cold stacking the covers.