Direct Attach

Direct Attach Cables are high-speed cable assemblies often used in datacenters and other areas where high bandwidth interconnections are needed.

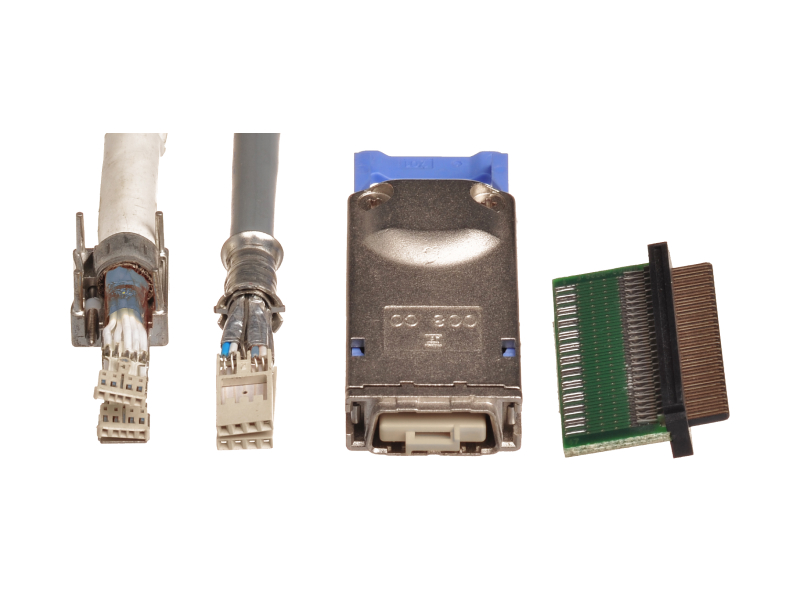

Direct attach cables can be passive or active. Passive cables are terminated with hot-soldered connectors like Infiniband or CXP, while active DACs (Direct Attach Cables) are finished with small plug-in devices like an SFP+, QSFP or DensiShield from Amphenol.

Föhrenbach Application Tooling offers an extensive range of solutions for almost any type of connector. From simple jigs for hand-soldering to automatic hot-bar soldering machines with 2D and 3D camera control, we cover your Direct Attach needs.

Direct Attach Solutions

The biggest advantage of direct attach cables is that they are plug and play. Factory tested, they offer high levels of performance and a guaranteed quality. This benefit can only be obtained through state-of-the-art DAC (Direct Attach Cable) production processes.

The production of Direct Attach High-Speed cable assemblies has 3 stages:

- Cable Preparation

- Cable Termination

- Post-Processing

Föhrenbach Application Tooling can offer you, upon request, an end-to-end solution to support your Direct Attach Cables manufacturing.

Cable Prep Techniques: Cutting cables to length, printing on cables, cable stripping, ….

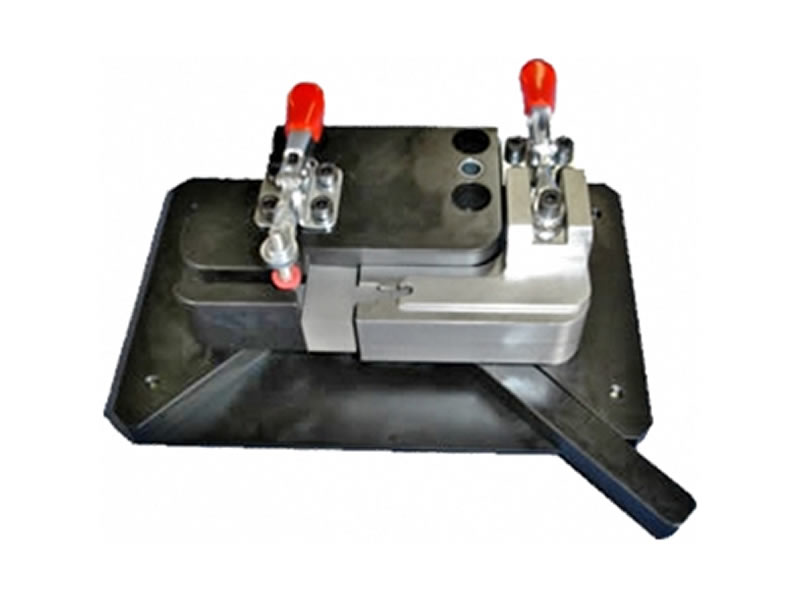

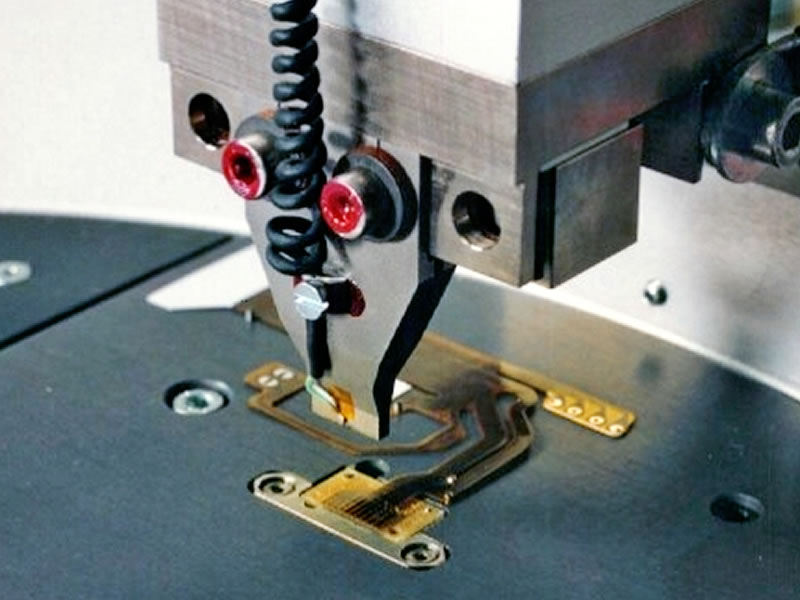

Cable Termination: Soldering, hot-bar soldering, ….

Post-Processing: Coiling, high-pressure over-moulding of strain reliefs, glueing (UV curing), low pressure over-moulding of the soldered PCB, continuity and high-voltage electrical testing, 2D and 3D camera control. cover closing, …

At Fohrenbach, we like a challenge, so you can ask us anything that could help you with the production of Direct Attach Cables. In fact, that counts for all your interconnection questions. Did we mention that depending on the type of connector,we can make tools for riveting or cold stacking connector covers and that we also support hot-bar soldering tools to attach for example flexible circuits to a PCB?