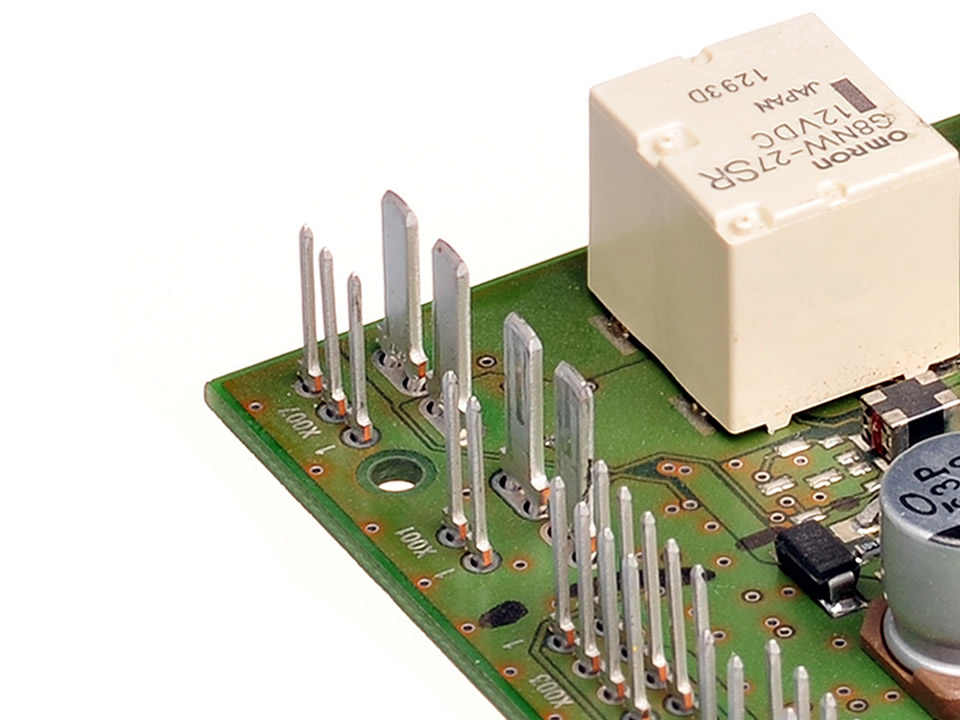

Single Pin Press-Fit

Single Pin Press-Fit is a solderless process used to mount contact pins on Printed Circuit Boards. The pins are inserted one by one into tightly matching holes in the PCB. It is widely used in the telecom and automotive industry as well as in safety electronics, fuse boxes and sensonics. The Föhrenbach Application Tooling family of ASPIM single pin Press-Fit solutions covers the full range of tools and machines, and are used globally for fast, secure and error free single pin Press-Fit applications. It is the right choice for manual contact insertion tools as well as for fully automated SMEMA compatible in-line machines. The ASPIM family accepts stamped and formed contacts as well as contacts in bandoleer format.

When designing our Press-Fit solutions, no compromises were made regarding insertion speed or quality. Our PSPIM pick-and-place standalone machine inserts on average 2 contacts per second while an ASPIM revolver-head based machine can easily reach 6 contacts per second. Our board editor with its intuitive UI accepts the Gerber or ODB++ data of PCBs to allow the fast development of complex pin-insertion patterns. In-process control and an optical board-error correction system complement the package making our ASPIM machines the industry reference for Single Pin Press-Fit applications.