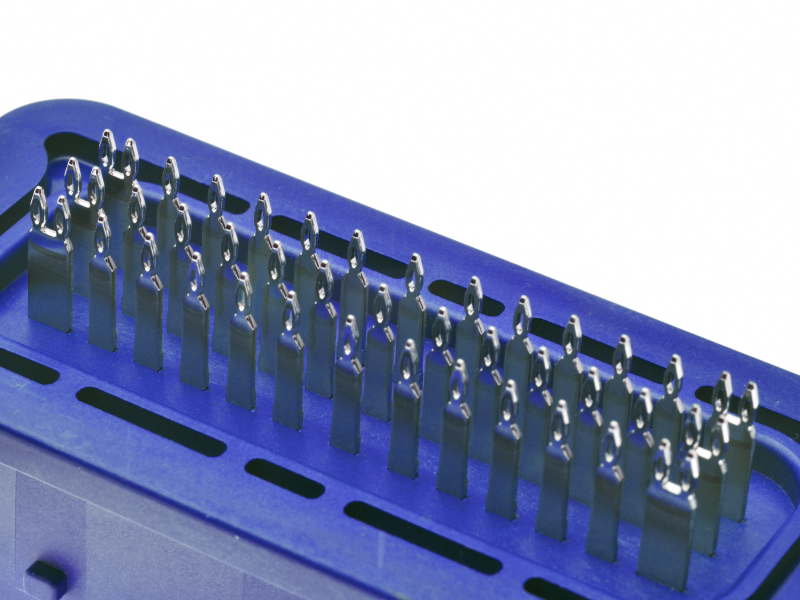

Pre Assembled Press-fit Connectors

Press-fit, sometimes called interference-fit or friction-fit, is a technology to make interconnections without soldering. Pre-Assembled Press-Fit connectors are already filled with contact pins that are then pressed into tightly fitting holes on a PCB. They are used to interconnect backing boards, motherboards, daughterboards and / or midplanes, but the family of Föhrenbach intelligent UNIPRESS solutions also allows Press-Fit into metal housings and other parts. In fact, our machines are not limited to processing Pre Assembled Press-Fit connectors but they can also be used for metal shields, springs and any other component that falls within the machines press capacity.

We chose a modular design concept. For small prototyping and repair jobs, we developed manual hand presses. Different levels of automation are available on our servo-controlled platforms, ranging from manual over semi-automatic up to fully automatic in-line pick-and-press machines. An optical board-error correction system, a component-error connection system, an integrated AOI system, a traceability system, a connection to your ERP system or whatever else you may need, rely on Föhrenbach Application Tooling for your standard or fully customized Pre-Assembled Press-Fit connectors solution!

Index